1. Basic principles and structural characteristics of corrugated design

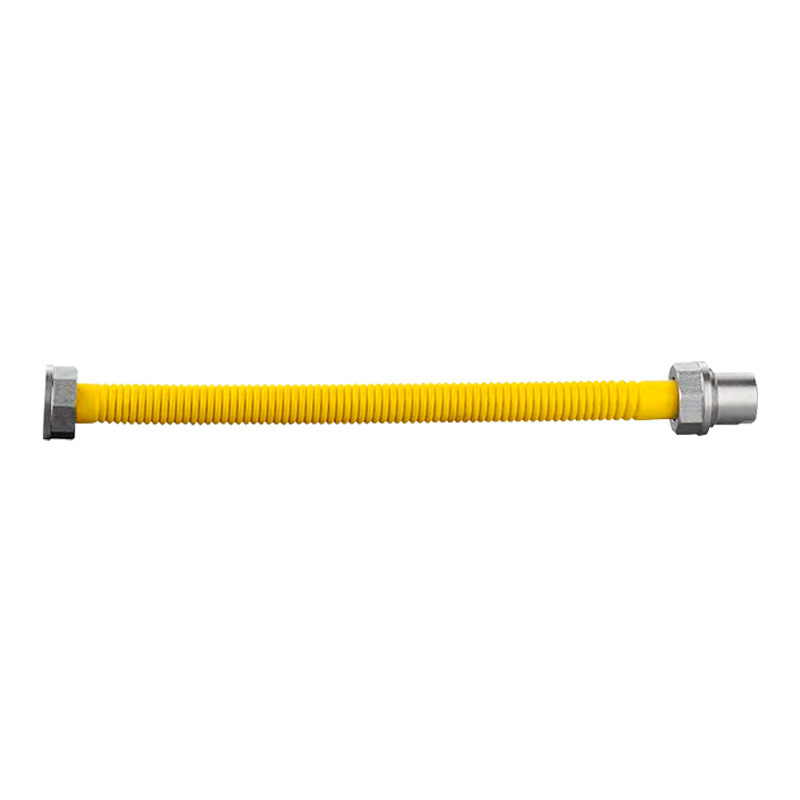

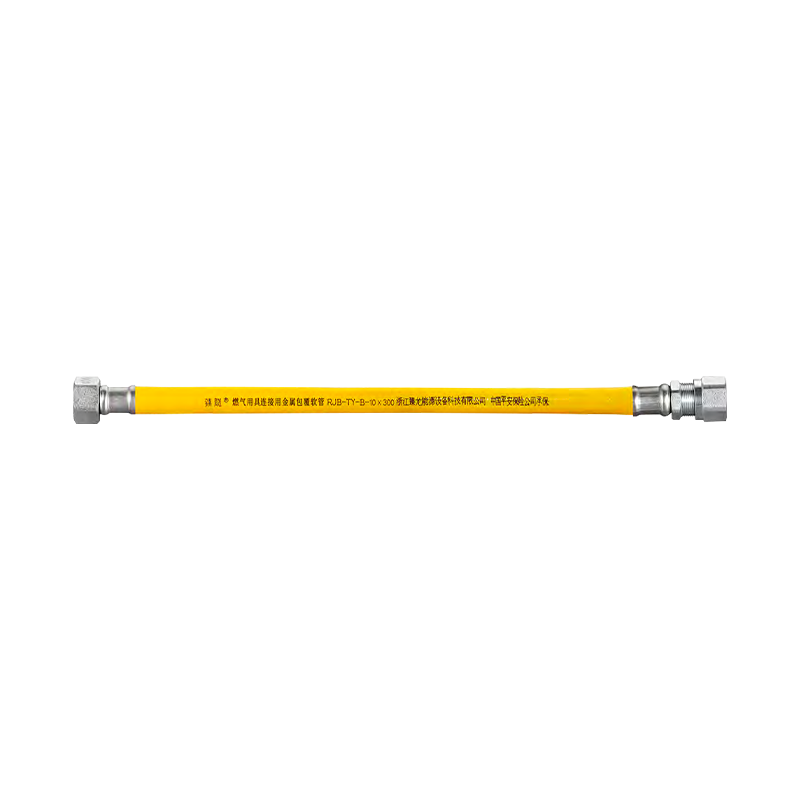

The core feature of Stainless Steel Plumbing Bellows is the corrugated structure of its inner wall, which presents the shape of peaks and troughs, similar to the "snake" design. The corrugated design of the bellows helps to improve the flow state of the fluid by increasing the surface area of the pipe. Unlike smooth pipes, the fluid inside the bellows will be disturbed when passing through the "bends" of the corrugations, causing changes in the flow velocity and turbulence of the fluid, breaking the boundary layer of conventional fluid flow.

2. How does the corrugated design affect water and air flow

Destroy the velocity boundary layer and enhance the turbulence effect

In traditional smooth pipes, a velocity boundary layer will be formed on the surface of the water or air flow. This layer of fluid flows slowly and is not conducive to the exchange of heat and substances. The corrugated structure of Stainless Steel Plumbing Bellows can destroy this velocity boundary layer, making the fluid more turbulent when flowing in the pipe, increasing the degree of disturbance and turbulence of the fluid.

Increase flow disturbance and form additional vortices

The corrugated design not only increases the turbulence of fluid flow, but also effectively forms additional vortices. Vortex is a flow pattern that can promote material exchange and heat transfer within the fluid. When water or air flows through the crests and troughs of the bellows, the fluid forms a circular vortex in the pipe, which quickly takes away local heat, making the heat distribution more uniform, thereby improving the efficiency of heat conduction.

Improve fluid flow and reduce pressure loss

Due to the turbulent and vortex characteristics of the flow inside the bellows, the flow of the fluid in the pipe can be more uniform and smooth, thereby reducing the pressure loss caused by uneven fluid flow. For hot water or gas systems, reducing pressure loss in the flow can effectively improve the efficiency of the system, reduce energy consumption, and extend the service life of the equipment. Compared with traditional pipes, Stainless Steel Plumbing Bellows exhibits higher fluid flow stability under high pressure and high temperature environments, reducing energy waste in the system.

3. The impact of corrugated design on water flow and air flow in different applications

Impact in heating system

In the heating system, when hot water flows through the bellows, the corrugated design can effectively promote the rapid conduction of heat, making the temperature change during the flow of hot water more uniform. When hot water passes through the bellows, turbulence and eddy currents accelerate the transfer of heat, allowing the hot water to transfer heat to the surrounding environment more quickly. Therefore, Stainless Steel Plumbing Bellows can not only improve the efficiency of heat exchange, but also maintain the stable operation of the system and ensure accurate temperature control.

Impact in industrial pipelines

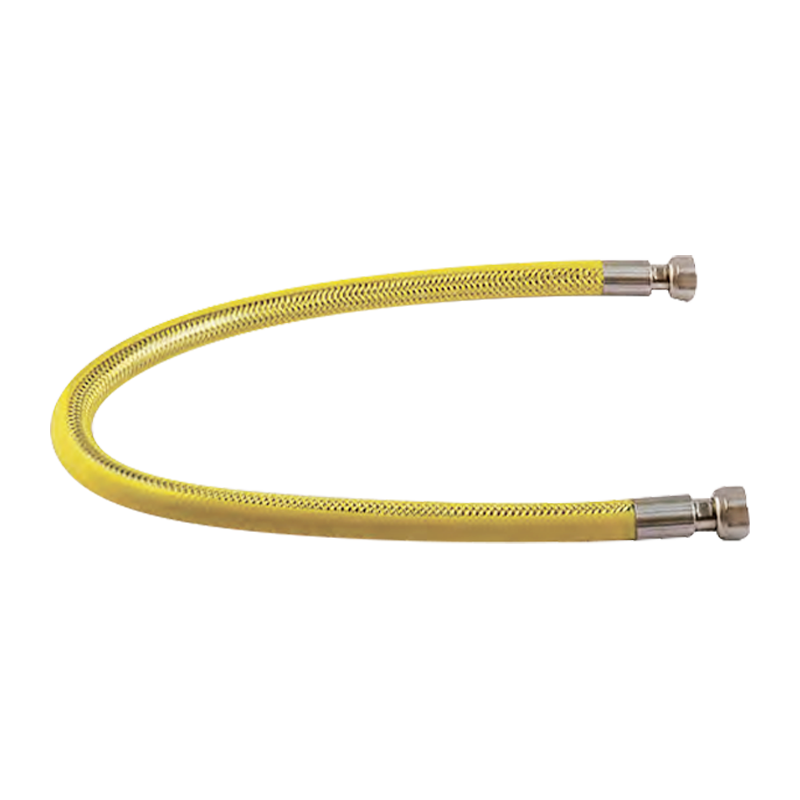

In industrial applications, especially in pipeline systems in industries such as chemicals and petroleum, the flow of fluids usually faces more complex pressure and temperature changes. The corrugated structure of Stainless Steel Plumbing Bellows can adapt to environments such as high pressure, deformation and vibration, while improving the flow efficiency of fluids in the pipeline.

Impact in air flow delivery

The application of Stainless Steel Plumbing Bellows in air flow delivery systems also has significant advantages. The peak and trough design of the bellows can effectively destroy the laminar flow phenomenon in the airflow, increase the mixing degree and turbulence of the airflow, and thus improve the flow efficiency of the gas in the pipeline. This improvement in flow state is of great significance to the energy consumption, pressure control, and temperature regulation of the gas pipeline system.

4. Other advantages of Stainless Steel Plumbing Bellows

In addition to improving the flow of water and air through the corrugated design, Stainless Steel Plumbing Bellows also have other excellent properties. For example, they have excellent corrosion resistance, high temperature and high pressure tolerance, and can operate stably in harsh working environments. At the same time, the flexible design of the bellows enables it to withstand thermal expansion, vibration, and pipeline displacement in the system, thereby ensuring the overall safety and reliability of the pipeline system.

English

English 中文简体

中文简体 Español

Español عربى

عربى