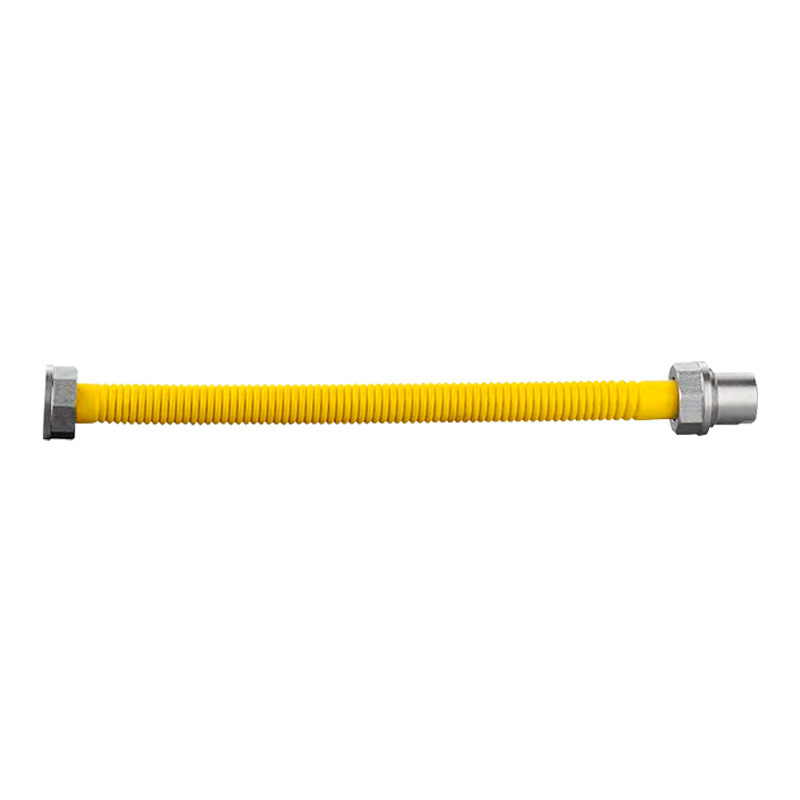

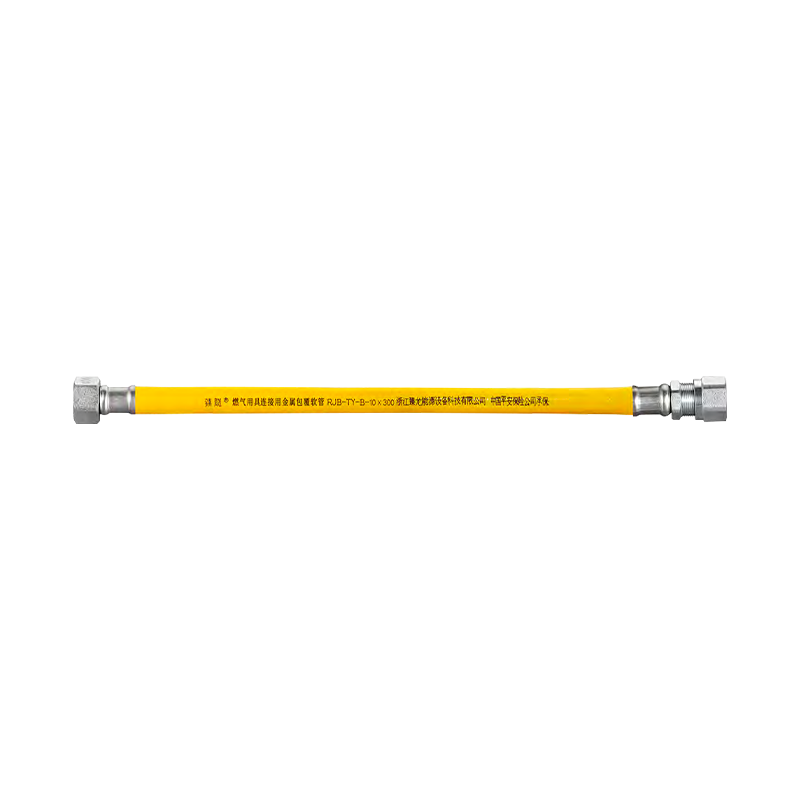

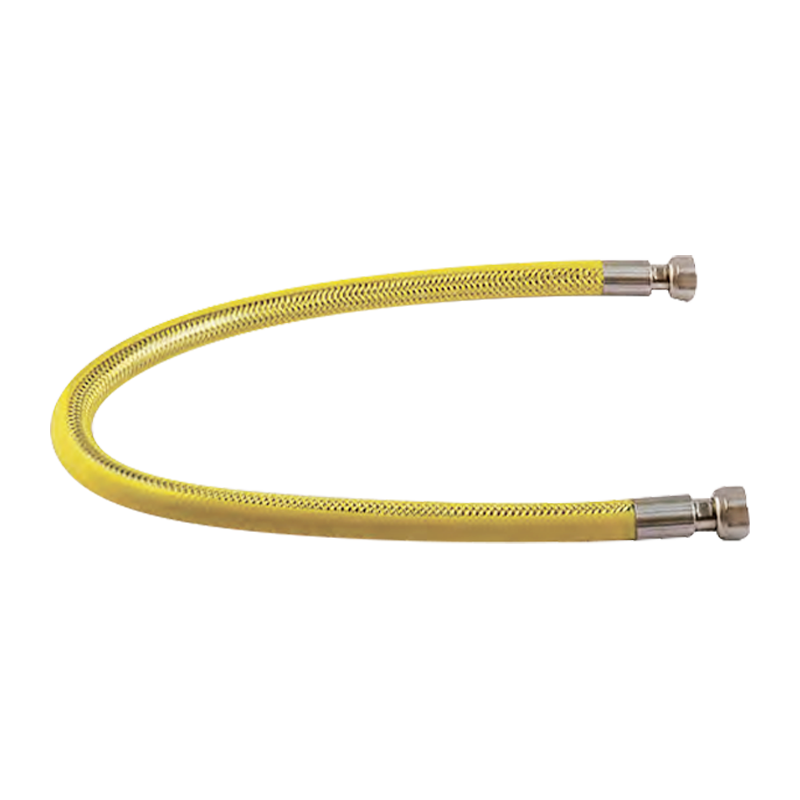

The design of stainless steel corrugated hose has been optimized and innovated in many aspects to reduce the risk of leakage, ensuring its high safety and reliability in various application environments. The corrugated structure gives the hose great flexibility, allowing it to easily adapt to various complex and changeable pipeline layouts, including right-angle turns, areas with large bending arcs, etc. This flexibility reduces the number of joints that must be added due to pipeline layout restrictions, thereby reducing potential leakage points. The corrugated structure can effectively disperse stress when subjected to repeated bending and vibration, reducing hose rupture or leakage caused by fatigue accumulation. This design is particularly suitable for use in occasions with large dynamic loads, such as near vibrating equipment or pipeline systems that need to be moved frequently.

304 and 316L stainless steel are commonly used materials for corrugated hoses. They show good resistance to most common corrosive media, including chlorine and sulfates in water. This ensures that the hose will not become thinner or perforated due to corrosion during long-term operation, thereby reducing the possibility of leakage. Stainless steel materials can maintain structural stability at higher temperatures and will not deform or rupture due to thermal expansion and contraction. This is particularly important for hot water supply systems or pipe systems close to heat sources, ensuring the continued safe operation of the system.

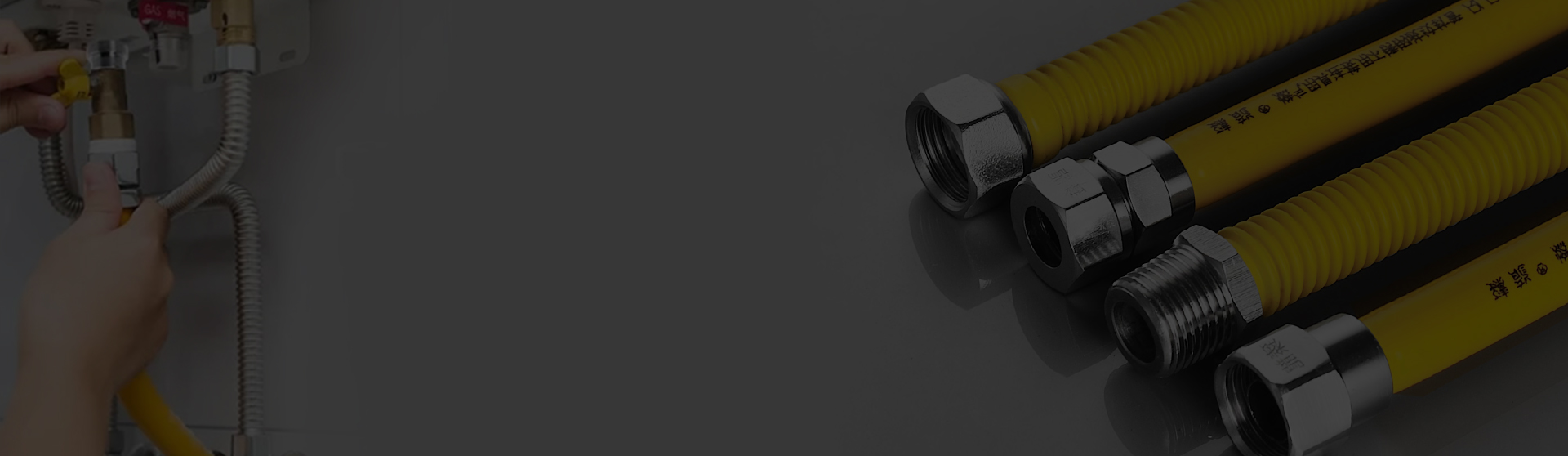

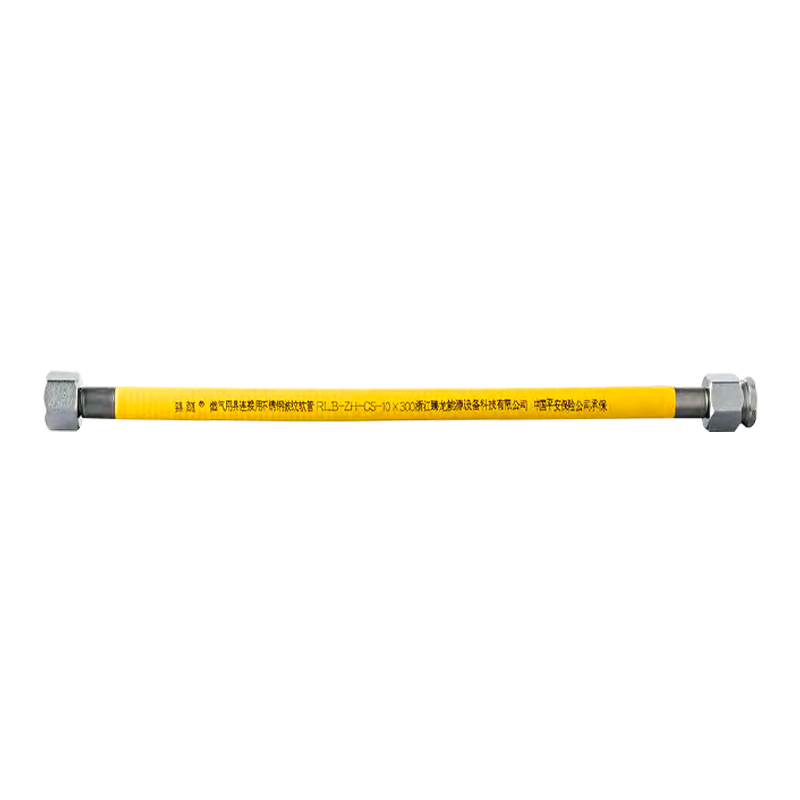

Stainless steel corrugated hoses usually use metal end fittings and are connected to the pipe system by threads, clamps or welding. The metal-to-metal seal is more secure than traditional rubber or plastic seals, is less susceptible to temperature and pressure changes, and reduces leakage caused by seal failure. Some high-end stainless steel corrugated hoses are also equipped with anti-loosening devices, such as locking nuts or thread lockers, to prevent the connectors from loosening due to vibration during use, further enhancing the stability and safety of the connection.

Stainless steel corrugated hoses can absorb pipeline displacement caused by foundation settlement, temperature changes or external forces, and prevent leakage caused by excessive stretching or compression of the pipeline. Its unique corrugated structure can also effectively isolate and absorb vibrations from mechanical equipment, fluid flow, etc., reduce the impact on the pipeline system and its connectors, extend service life, and reduce the risk of leakage.

Because the stainless steel corrugated hose itself has excellent bending performance, it does not need to rely too much on additional pipe fittings such as elbows and tees during installation, which simplifies the pipeline system and reduces potential leakage points. Stainless steel corrugated hoses reduce leakage risks in all aspects through their unique structural design, selection of high-quality materials, reliable connection methods, efficient displacement compensation and vibration absorption capabilities, and reduced use of additional pipes, providing safe and reliable fluid transmission solutions for various industrial and commercial applications.

English

English 中文简体

中文简体 Español

Español عربى

عربى